About Ohm Engineers

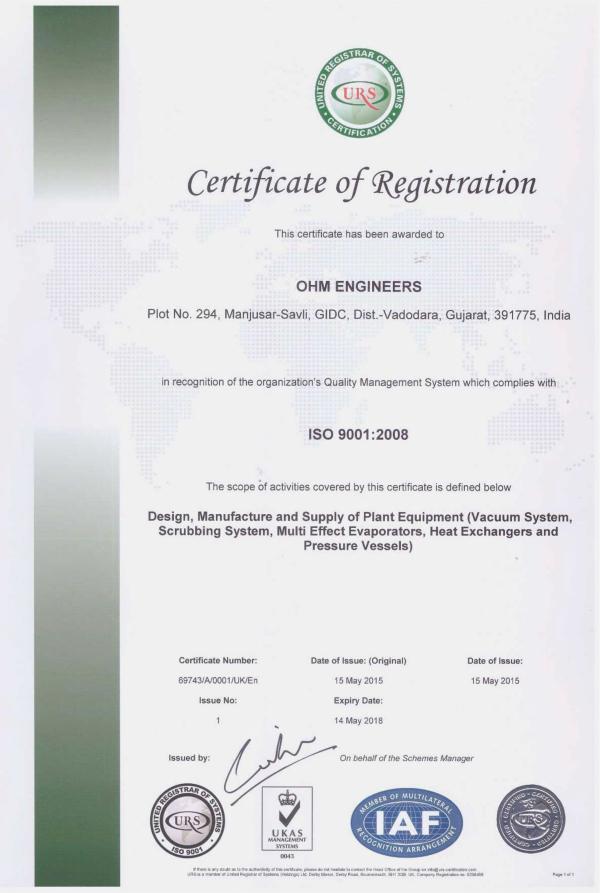

ISO Certificate

Quality Policy

We at Ohm Engineers, are involved in providing quality technology solutions, Design, Manufacturing, supply, implementation and after sales services for Process Plant equipments (Heat Exchanger, Pressure vessel, Distillation Column, U-Tube Heat Exchanger etc.) and Vacuum Technology & committed to comply with Quality Management System requirements with continuously improvising its effectiveness; delivering timely & cost effective solutions / services to meet the expectation of our customer vis-a-vis satisfying applicable statutory & regulatory requirements.

Company Profile

Ohm Engineers were established in 2004 by a group of Engineers ewith wide experience in Process Engineering.

We are in the field of Design, Manufacturing and Supply of Process Plant Equipment viz. Heat Exchangers, U Tube Heat Exchangers, Distillation Columns, Reactors, Scrubbing Systems, Multi Effect Evaporator Systems and Vacuum Systems including Steam/Liquid Jet Vacuum Ejectors. We follow international standards like ASME, TEMA etc in design.

Our products are widely used in Chemical, Pharma, Oil & Gas, etc.

Since 2004, we have offered innovative, competitive and result oriented solutions incorporating conventional and advanced technologies, to our clients. We are established entity in our expertise in Vacuum Systems, process equipments through our consistent quality, workmanship, and timely supplies / completion of projects at very competitive prices while maintaining quality standards.

We have best of the industry professionals as key people to input their vast & subject specific experience to design & implement most suitable & state of the art solutions for our customers, which can deliver the best output & overall performance to the satisfaction against investment.

We at Ohm Engineers are focused to the Total Quality Management.

Vision

To be a global leader in providing Solutions to Process Plant equipments (Heat Exchanger , Pressure vessel , Distillation Column , U-Tube Heat Exchanger etc.), Vacuum Technology, engineering services & turnkey projects for the process industries through continuous self improvement & updating with the recent & forth coming technologies & challenges.

Mission

At Ohm Engineers, we strive to accomplish the following:

- Understanding the need of the users and providing the solutions with best suitable material of construction & its efficient & cost effective management through our experience & technological expertise.

- Facilitate discussions & inputs on Energy Efficient & cost effective solutions to reduce the quantity of wastes that need to be disposed in Zero Discharge Solutions

Company and Contact Information

| Registered Company | Ohm Engineers |

| Registered Office (Unit -1 & Unit - 2) |

348, G.I.D.C. Manjusar-Savli, Tal.Savli, Dist. Vadodara – 391775, Gujarat, India |

| Office Contacts | +91 83470 19128 / +91 83470 19122 E-mail : ohmengineers@gmail.com, info@ohmengineers.co.in, sales@ohmengineers.co.in |

| Factory Address | As above |

| GST No | 24AADFO4347H1ZD |

| Commission Rate | VADODARA |

| Bankers | Bank Of Baroda, Union Bank of India |

| Account Name | OHM ENGINEERS |

| EC No | 3413004107 |

| MSME | G J 24B0001119 |

Products & Services

In the core domain of Design, Manufacturing & Supply of Process Plant Equipment, Vacuum Systems, Thermo Compressor etc., as mention below.

Our products are as below :

- Heat Exchanger

- U-Tube Heat Exchanger

- Reactors

- Distillation Cum Fractionation Columns

- Pressure Vessels

- Dosing System etc.

- Multi-Effect Evaporator

- Steam / water jet Vacuum System

- Thermo Compressor

- Ventury Gas Scrubber

- food & Dairy plant Equipments

Infrastructure & Facility at our Unit-1 & Unit-2

We have good quality manufacturing equipments and working area likes,

Unit – 1 :- (294 Manjusar G.I.D.C Savali, Baroda)

Total Area: 1000 Sq.Mtr

Working Area: 372 Sq.Mtr

Power Connection: 90 H.P

| Sr. No. | Description | Qty. |

|---|---|---|

| 1 | Welding Rectifiers 400 Amp. (Quality Make) | 4 Nos. |

| 2 | Inverter base Welding Rectifiers Kemppi Make) 250 Amp 350 Amp |

2 Nos. 1 Nos. |

| 3 | Plasma cutting up to 20mm (Quality Make) | 1 Nos. |

| 4 | Pug Cutting Machine up to 60mm (Koki Make) | 1 Nos. |

| 5 | Lathe Machine (V-bed, 250 center height, 4ft long bed ) | 1 Nos. |

| 6 | Radial Drill up to 40mm (India Make) | 1 Nos. |

| 7 | Tubes Expanders Digital (Power Master Make) | 1 Nos. |

| 8 | Power Tools (AG-4,AG-5,AG-7,Gq-4,Flexible grinder, hand drill etc) | 8 Nos. |

| 9 | Magnate Drill (Nippon Make) | 1 Nos. |

| 10 | Gas Cutting (Koike Make) | 2 Nos. |

| 11 | Over Head Crane (10 Tonn) | 1 Set. |

| 12 | Bench Grinder | 1 Nos. |

| 13 | Air Compressor (7.5 H.P) | 1 Nos. |

Unit – 2 :- (348 Manjusar G.I.D.C Savali, Baroda)

Total Area: 1000 Sq.Mtr

Working Area: 500 Sq.Mtr

Power Connection: 100 H.P

| Sr. No. | Description | Qty. |

|---|---|---|

| 1 | Welding Rectifiers 400 Amp. (Quality Make) | 2 Nos. |

| 2 | Inverter base Welding Rectifiers Kemppi Make) 400 Amp |

5 Nos. |

| 3 | Plasma cutting up to 35mm with air compressor 7.5 hp | 1 Nos. |

| 4 | Lathe Machine 22" center height, 16' bed heavy duty | 1 Nos. |

| 5 | Radial Drill up to 65mm (HMT RM65) | 1 Nos. |

| 6 | Hand sharing 6mm SS Cutting | 1 Nos. |

| 7 | Power Tools (AG-4,AG-5,AG-7,Gq-4,Flexible grinder with buffing attachment, hand drill etc) | 10 Nos. |

| 8 | Gas Cutting (Koike Make) | 1 Set. |

| 9 | Over Head Crane (20 Tonn) | 1 Nos. |

| 10 | Bench Grinder | 1 Nos. |

| 11 | Air Compressor (as above) | 1 Nos. |

Our business associates in UAE

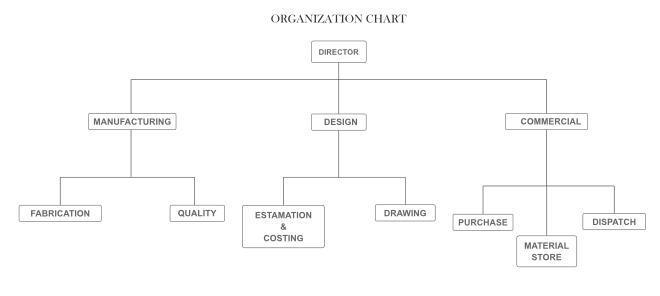

Organizational chart